Tungsten bucking bar

Tungsten Bucking Bar introduction

Bucking bar is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted tool head and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear.

Bucking bars are used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Bucking bars used to form buck tails on rivets. And come in many different shapes and sizes. They are normally made from alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

The size and weight of the bar depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars are manufactured locally.

Our bucking bars are normally made from tungsten heavy alloy. All edges are deburred and working surfaces are polished for troubles-free use. This helps to prevent marring of formed buck tails. Please notice that never hold a bucking bar in a vise unless the vise jaws are equipped with protective covers to prevent marring of the bucking bar.

| Item | Description | Item | Description |

|---|---|---|---|

|

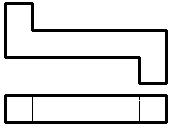

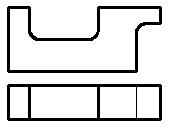

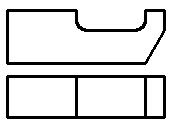

Code: Specification: Weight:603g |

|

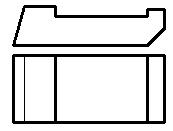

Code: Specification: Weight:744g |

|

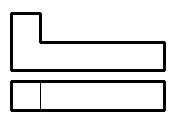

Code: Specification: Weight:680g |

|

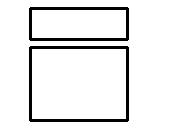

Code: Specification: Weight:2540g |

|

Code: Specification: Weight:1792g |

|

Code: Specification: Weight:1787g |

|

Code: Specification: Weight:720g |

|

Code: Specification: Weight:603g |

|

Code: Specification: Weight:1315g |

|

Code: Specification: Weight:757g |

All of our Tungsten Bucking Bars are made of 90+% W tungsten heavy alloy products. With the advantage of being more than twice as dense as steel, tungsten bucking bar now becomes the best choice for riveting, especially for the confined spaces. With a suitable bucking bar, you will make the task easier and perfect, meaning less rivets to drill out.

Related Links

Material Safety Data Sheet of Tungsten Alloy

Material Safety Data Sheet of Tungsten Alloy (PDF)

Catalog of Tungsten Alloy Products (PDF)

sales@chinatungsten.com

sales@chinatungsten.com